Different Types of Pattern

→ In casting process, Pattern is the replica of the device which is the output of casting process. This when molded in sand forms mold. After filling mold with the molten metal there is a formation of casting. Patterns play a very important role in casting as they decide the quality as well as perfection in a particular casting process. Gates and runners are the most important components in several types of pattern. Pattern is the basic requirement for creation of mold and it is always bigger than the size of casting. There should be a proper selection of pattern …

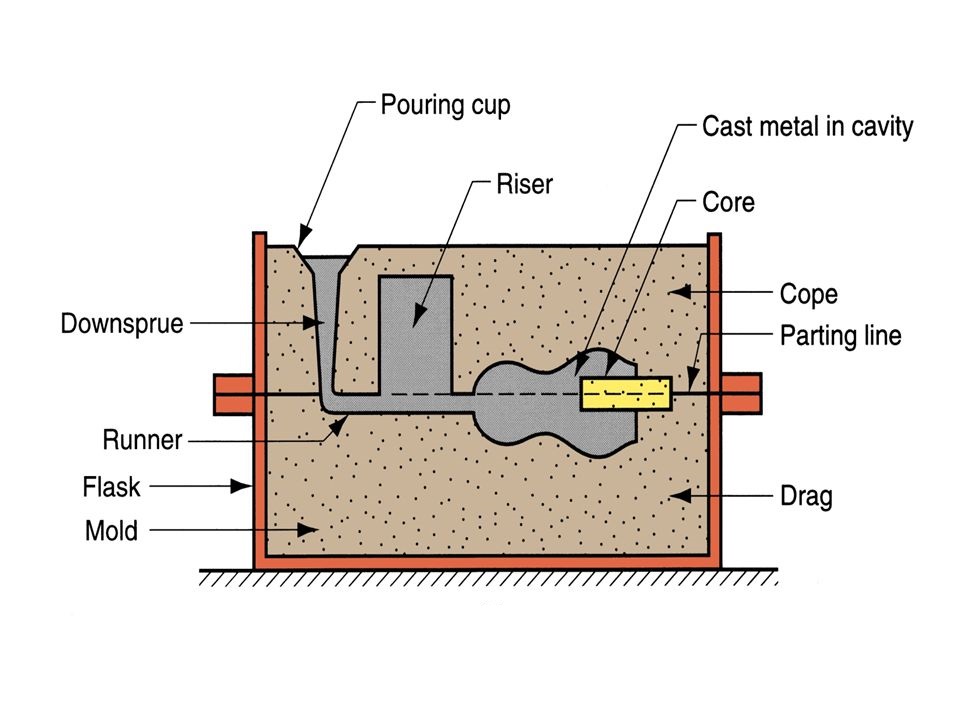

CASTING TERMINOLOGY

CASTING TERMINOLOGY → (1) FLASK:- The Flask is the box that contains the moulding aggregate. → (2) Pattern:-It is the replica of the final object to be made with some modification. → (3) Parting Line:-This is dividing line b/w two parts of flask that makes the sand moulds. → (4) Bottom board:- This is normally made of wood which is used to support the one end of the flask. → (5) Facing sand:- The Small amount of carbonucous sand material sprincal on the internal mould surface of cavity to give better surface finish to the casting. → (6) Moulding Sand:- …

ADVANTAGES OF CASTING PROCESS OVER OTHER MANUFACTURING PROCESS.

ADVANTAGES OF CASTING PROCESS OVER OTHER MANUFACTURING PROCESS. …

Classification of Manufacturing process

Manufacturing Process may be classifies under following head. (A).Shaping or Forming:- -Manufacturing a solid product of define size and shape from a given material taken in three possible states: → In solid State:- eg. Forging, Rolling, Extrusion, Drawing etc. →In Liquid or semi liquid state:- eg. Casting, Injection moulding etc. →In powder from:- eg. Powder Metallurgy. (B). Joining process welding, brazing,soldering etc. (C).Removal Process Machining( traditional or Non-traditional) Grinding ⇒Based on the nature of work involved these processes may be devide into following seven Categories:- (1) Processes for changing Physical properties of the material:- →Hardening, Tempering,Anneling,Surface Hardning. (2) Casting Process:- …