Highlights

Quick access mixing chamber’s dual doors using single spanner.

BE Provide Wear Resistance Mixing blade which is brazed by the tungsten carbide material.

Double safety system incorporating time delay interlocks to prevent access until mixer shaft is at rest.

Powered primary and mixing arm slewing available.

BE Provide highly precision pumps for homogeneous mixing of sand and Binder.

Robust Rugged and Heavy duty construction design for years of use and abuse with minimum maintenance and quality ensures vibration free operation.

BE mixer are simple in design and easy to operate.

BE supplied 100 % Complete fully assembled for easy and quick installation.

One Year Mechanical Parts Warranty.

System Overview

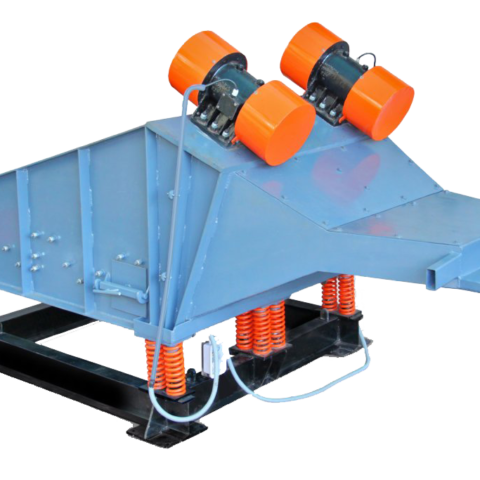

Mixing Chamber: – BE mixing chambers feature ultra-heavy construction. The regenerative sand lining protects the primary fabrication while imparting the highest mixing efficiency possible. Heavy gage steel chambers with turned, ground, and polished mixer shafts are standard.

Mixing Blades: – All BE blades feature harden by Brazing of Tungsten Carbide. These blades offer extremely long life.

Pumping Systems: – All BE mixers feature as Highly Precise Pump by grinding process. BE’s resin delivery system ensures consistent resin flow and greatly reduced effects of resin viscosity changes as compared to others. A PLC is used to control all critical mixer timing functions to ensure usable every drop of resin and catalyst. The pumping system is housed in a separate enclosure to protect the components from the plant environment.

Control System: – All BE mixers are fitted with a high quality electrical control system featuring standard OEM components and complete control integration. A PLC is used to control all critical mixer timing functions to ensure usable first and last sand.

Air Jets: – All BE mixers feature easily removable resin delivery jets. Using the Flow Control, the operator can easily calibrate at the actual point of resin entry, not a remote ball valve as others do. A low flow air assist keeps the resin ports open and aid in the up-front blending of resin onto the sand.

Mixing Head Assembly:

The mixing chamber is a drive by motor which is made from heavy walled tubing that is externally reinforced for maximum rigidity and stiffness.

The mixing chamber doors feature heavy-duty quick release Nut that allow for simple, easy access to the interior of the chamber. The doors are hinged at the end and swing left and right side to allow complete access to the mixing blades and driveshaft. The hinged doors eliminate all ergonomic problems associated with the removal of fabricated components from the mixer.

The mixing blades are faced with thick tungsten carbide and are adjustable position blade with predetermined angles and head heights. This greatly simplifies the replacement process and eliminates the need for constant blade inspection and adjustment found with other blade designs.

The mixing blades are overlapping and sized to allow a build-up of resinous material that creates the lining of the inside of the mixing chamber. This lining provides an optimum relationship between the end of the blade and the interior diameter of the chamber. It is constantly maintained by each blade wear as it occurs. With this lining as an intentional part of the mixing chamber, the daily cleaning consists of only removing the build-up on the mixing blades and driveshaft.

The mixing chamber is designed to be as rugged yet simple as possible. The fixed position mixing blades, close tolerance regenerative lining, and high speed rotation provide and extremely intense blending action with a minimum amount of cleaning and maintenance.