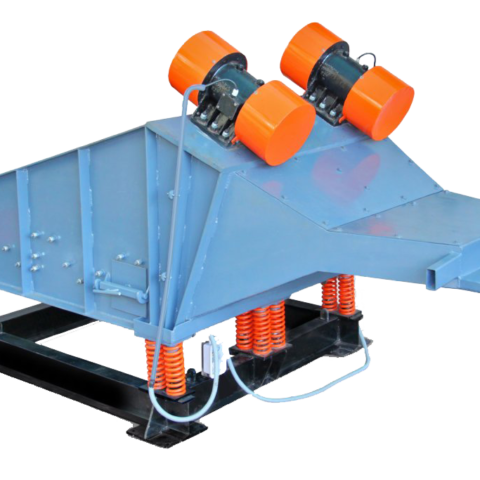

Bowl Mixer for No-Bake & Co2 Moulding Process

BE Super Speed Batch Mixers are a totally automatic batch mixing system for high speed preparation of all types of sand mixes for Core Sand & Moulding Sand for small scale foundry. It is available for No-Bake process and CO2 Process. Remarkable performance in high intensity mixing efficiency, accuracy and application flexibility is achieved in this machine. This high intensity mixing action allows significant reduction in binder usage in when compared with most conventional mixing equipment. PLC is used as heart of the control system to provide wide flexibility in automatic operation. All sand mix variables are pre-programmed to allow accurate control of any desired sand mix.

“S“ type mixing blade provides intensified mixing action to achieve outstandingly efficient use of all binder systems. Rotational speed of this Mixing Blade is substantially more than the conventional Bowl Mixers. Automatic self cleaning is programmed to occur at the completion of each single batch or at the completion of continuous batching. During this operation, a measured amount of dry sand is introduced into the Mixer and the Mixing Blade continues to rotate for a short time period using this sand to provide a scouring action. This sand remains in the pan of the Mixer and becomes an integral part of the next automatic batch. At the start of the next batch, sand is added according to the batch size and allowance is automatically made for the measured amount of scouring sand already present.