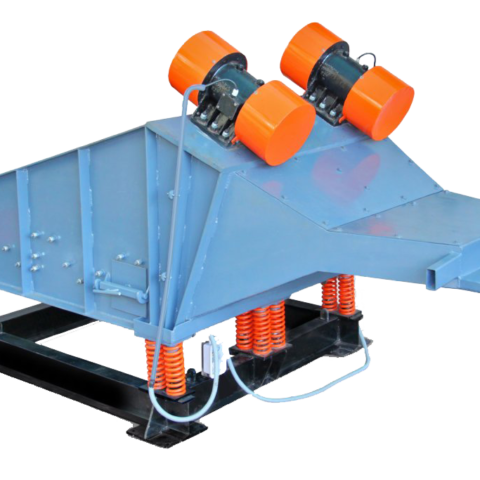

Pneumatic Conveyor

‘BE’ Pneumatic Thrust conveying is a discontinuous transport process from a closed vessel. It operates according to the cycle “fill – transport “. Compressed air thrusts the bulk material out of the pressure vessel through a transport pipe. In this conveying process, the cross section of the pipe immediately following the pressure vessel is completely filled.

Depending on the setting and the properties of the product, plugs form, and the distance between these plugs increases. There is, however, no dispersed conveyance. The pneumatic conveyor is especially suitable for conveying dry, granular and free – following substances.

The pneumatic conveyor is never fully emptied, so that each conveying process takes place against the full line. This reduces pipe wear and material abrasion considerably. They are compact in design, require little maintenance and make little noise.