CASTING TERMINOLOGY

CASTING TERMINOLOGY

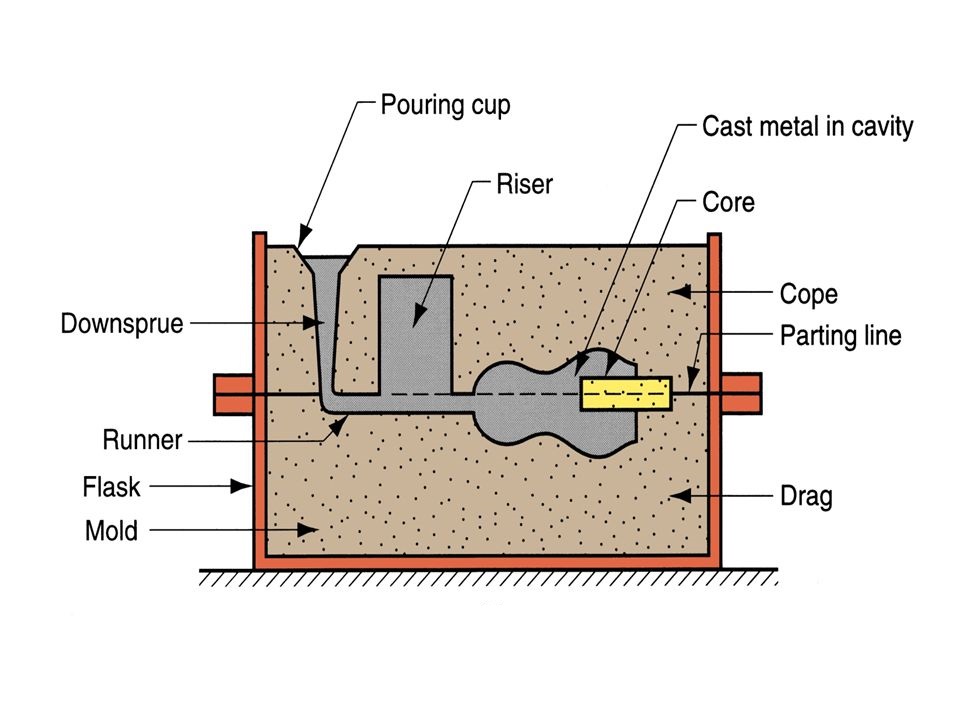

→ (1) FLASK:- The Flask is the box that contains the moulding aggregate.

→ (2) Pattern:-It is the replica of the final object to be made with some modification.

→ (3) Parting Line:-This is dividing line b/w two parts of flask that makes the sand moulds.

→ (4) Bottom board:- This is normally made of wood which is used to support the one end of the flask.

→ (5) Facing sand:- The Small amount of carbonucous sand material sprincal on the internal mould surface of cavity to give better surface finish to the casting.

→ (6) Moulding Sand:- It is Freshly Prepare refrectory use for making the mould cavity.

→ (7) Backing Sand:- It is the bulk of the sand used to back up the facing sand & to fill up the volume of the flask.

→ (8) Pouring basin:- A Small Funnel Shaped Cavity at the top of mould in to inch the molten metal is poured.

→ (9) Core:- A core is used in Casting and moulding Process to produce internal hollow cavities in final product.

→ (10) Sprue:- It is Vertical Cavity in the mouls to flow the molten metal from the pouring basin.

→ (11) Runner:- The pass way in the parting line through which molten metal regulated before they reach to mould cavity.

→ (12) Chills:- Chilles are metalic object which are placed in mould to increase the cooling rate of the casting.

→ (13) Chaplet:- It is used to support core inside the mould cavity to take core of it’s own weight & over come meler lostetic Forces.

→ (14) Riser :- It is reservior of molten metal provided in casting show that metal can flow back into the more cavity there is a reduction in volume of metal due to solidify.