CENTRIFUGAL CASTING PROCESS

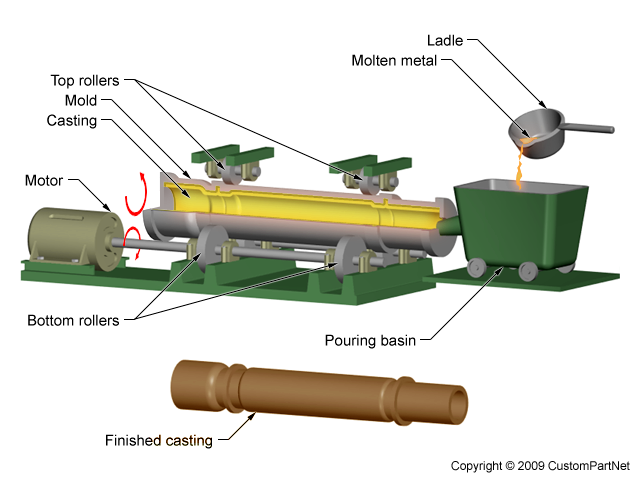

CENTRIFUGAL CASTING PROCESS – A family of casting processes in which the mold is rotated at high speed so centrifugal force distributes molten metal to outer regions of die cavity this process known as Centrifugal Casting Process. This process is widely use for the Pipe manufacturing. Types of Centrifugal Castings True Centrifugal Casting Semi-Centrifugal Casting Centrifuge Casting True Centrifugal Casting Molten metal is poured into a rotating mold to produce a tubular part In some operations, mold rotation commences after pouring rather than before Rotational axes can be either horizontal or vertical Parts: pipes, tubes, bushings, and rings Outside shape of …

TYPES OF GATING SYSTEM IN CASTING PROCESS

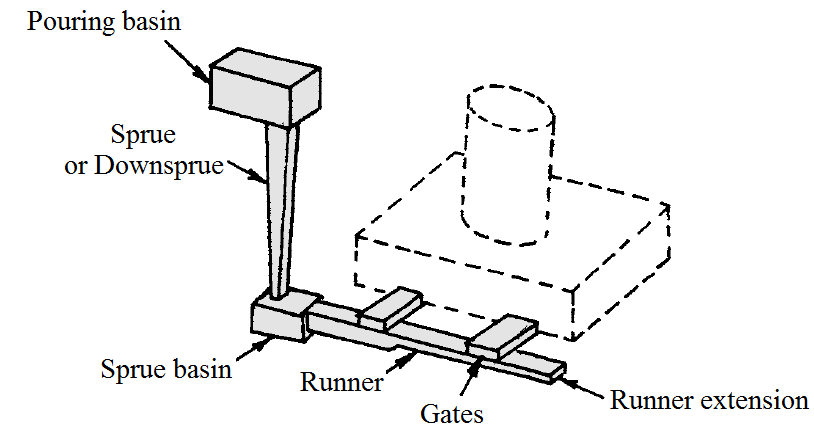

TYPES OF GATING SYSTEM IN CASTING PROCESS Mould is used for producing a casting. Molten metal is conveyed into the mold cavity by using Gating system. In casting process, gating system plays an important role to produce a high quality casting. A poorly designed gating system results in casting defects. A gating system controls mould filling process. The main function of gating system is to lead molten metal from ladle to the casting cavity ensuring smooth, uniform and complete filling. Elements of Gating System Pouring Cup Spruce Spruce Well Cross-gate or Runner Ingate or Gates Pouring Cup – It is …

STEPS FOR MAKING SAND CASTINGS

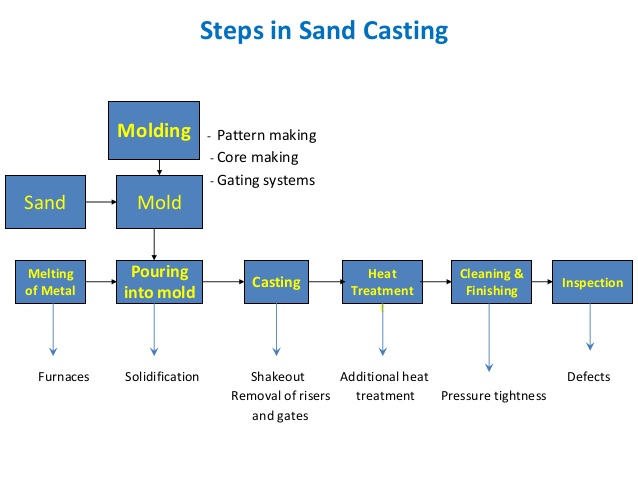

STEPS FOR MAKING SAND CASTINGS Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a …

What Is Heat Treatment Process ?

Are you curious to know what is heat treatment process? What are the types of it? Well, in this blog you will get answers of all these questions. So, let’s get started. Heat treatment process is a technique in which metals in the solid state are subjected to heating and cooling processes. The basic purpose of heat treatment process is to change the physical properties of the metal. The physical properties like ductility, malleability, hardness can be altered with this heat treatment process. These physical and mechanical properties of the metal are changed in such a way that it becomes …

Forging Process V/S Casting Process

In this Blog I will Explain about forging vs casting. In the manufacturing process these two processes forging and casting is very crucial. Without them it is impossible to make any machinery, tools, shape etc. Forging and casting both are used in the manufacturing industries but they have a lot of difference between them. Here we will discuss about forging vs casting in detail. What is Forging? It is a processes in which the metals and alloys are changed to the specific shape by compressive forces exerted by some external agencies. These external agencies may be hammers, rolls, press and an upsetting …

Dense Phase Pneumatic Conveying System

Dense Phase Pneumatic Conveying System ‘BE’ Pneumatic conveying System is a discontinuous transport process from a closed vessel. It operates according to the cycle “fill – transport”. Compressed air thrusts the bulk material out of the pressure vessel through a transport pipe. In this conveying process, the cross section of the pipe immediately following the pressure vessel is completely filled. Depending on the setting and the properties of the product, plugs form, and the distance between these plugs increases. There is, However, no dispersed conveyance. The pneumatic conveyor is especially suitable for conveying dry, granular and free – following substances. …