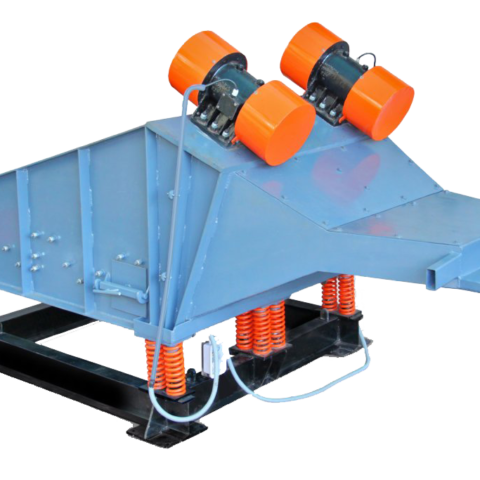

Dense Phase Pneumatic Conveying System

Dense Phase Pneumatic Conveying System

The pneumatic conveyor is never fully emptied, so that each conveying process takes place against the full line. This reduces pipe wear and material abrasion considerably. They are compact in design, require little maintenance and make little noise.

Applications

• Foundry and Steel Industries

• Chemical and Pharmaceutical Industries

• Glass and ceramic Industries

• Plastic Industries

• Food and Feed Industries

Features

• Compact & Fully Automatic

• Negligible power consumption

• Only compressed air used for conveying

• Low wear, tear and maintenance

• No moving parts in the material to be transported

• Economical operation.

Range : Starting from 500 Kg/hr. to 15 Tons/hr.