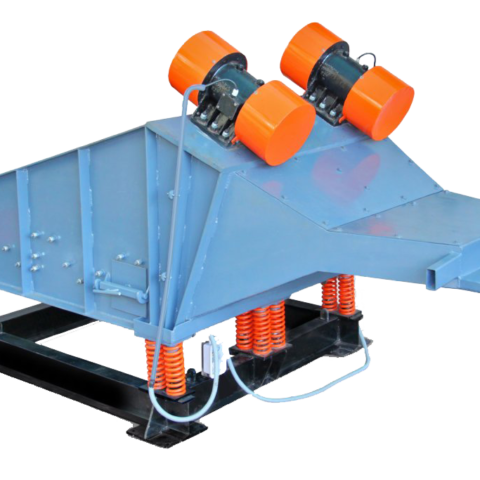

Dense Phase Pneumatic Conveying System

Dense Phase Pneumatic Conveying System ‘BE’ Pneumatic conveying System is a discontinuous transport process from a closed vessel. It operates according to the cycle “fill – transport”. Compressed air thrusts the bulk material out of the pressure vessel through a transport pipe. In this conveying process, the cross section of the pipe immediately following the pressure vessel is completely filled. Depending on the setting and the properties of the product, plugs form, and the distance between these plugs increases. There is, However, no dispersed conveyance. The pneumatic conveyor is especially suitable for conveying dry, granular and free – following substances. …

Classification of Manufacturing process

Manufacturing Process may be classifies under following head. (A).Shaping or Forming:- -Manufacturing a solid product of define size and shape from a given material taken in three possible states: → In solid State:- eg. Forging, Rolling, Extrusion, Drawing etc. →In Liquid or semi liquid state:- eg. Casting, Injection moulding etc. →In powder from:- eg. Powder Metallurgy. (B). Joining process welding, brazing,soldering etc. (C).Removal Process Machining( traditional or Non-traditional) Grinding ⇒Based on the nature of work involved these processes may be devide into following seven Categories:- (1) Processes for changing Physical properties of the material:- →Hardening, Tempering,Anneling,Surface Hardning. (2) Casting Process:- …