Pouring & Gating Design

Pouring & Gating Design A good gating design should ensure proper distribution of molten metal without excessive temperature loss, turbulence, gas entrapping and slags. If the molten metal is poured very slowly, since time taken to fill the mould cavity will become longer, solidification will start even before the mould is completely filled. This can be restricted by using super heated metal, but in this case solubility will be a problem. If the molten metal is poured very faster, it can erode the mould cavity. So gating design is important and it depends on the metal and molten metal composition. For example, aluminium can get …

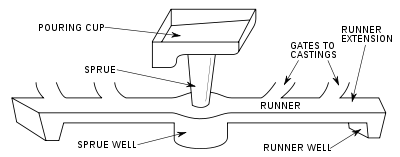

CENTRIFUGAL CASTING PROCESS

CENTRIFUGAL CASTING PROCESS – A family of casting processes in which the mold is rotated at high speed so centrifugal force distributes molten metal to outer regions of die cavity this process known as Centrifugal Casting Process. This process is widely use for the Pipe manufacturing. Types of Centrifugal Castings True Centrifugal Casting Semi-Centrifugal Casting Centrifuge Casting True Centrifugal Casting Molten metal is poured into a rotating mold to produce a tubular part In some operations, mold rotation commences after pouring rather than before Rotational axes can be either horizontal or vertical Parts: pipes, tubes, bushings, and rings Outside shape of …

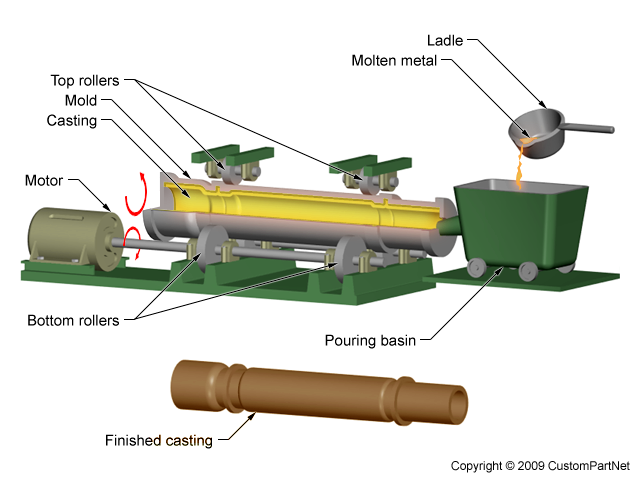

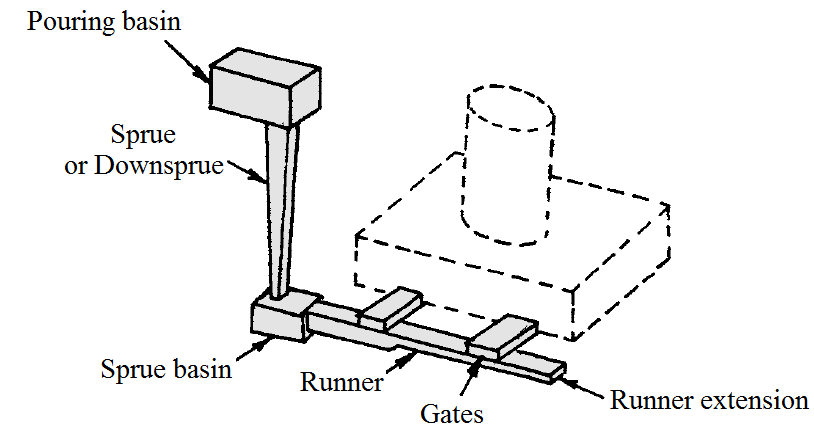

TYPES OF GATING SYSTEM IN CASTING PROCESS

TYPES OF GATING SYSTEM IN CASTING PROCESS Mould is used for producing a casting. Molten metal is conveyed into the mold cavity by using Gating system. In casting process, gating system plays an important role to produce a high quality casting. A poorly designed gating system results in casting defects. A gating system controls mould filling process. The main function of gating system is to lead molten metal from ladle to the casting cavity ensuring smooth, uniform and complete filling. Elements of Gating System Pouring Cup Spruce Spruce Well Cross-gate or Runner Ingate or Gates Pouring Cup – It is …

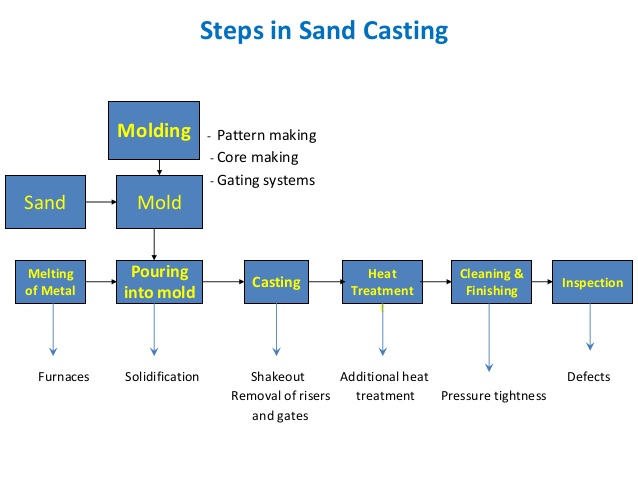

STEPS FOR MAKING SAND CASTINGS

STEPS FOR MAKING SAND CASTINGS Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a …

Colgate-Palmolive renews with Morz in Malaysia

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …

BMW’s new Z4 convertible is being developed alongside new Toyota Supra

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …

Oil prices rise as investors focus on U.S. data

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …

Why Trump is so clumsy about fighting ‘Free Trade’

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …

Stock buybacks hurt workers and the economy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …

Influencing the influencer

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam efficitur rutrum diam, ut commodo ipsum elementum. Duis quis iaculis purus, eget mattis urna. Quisque consectetur odio ac ante fermentum malesuada. Nullam eget lectus euismod, rutrum quam quis, venenatis ligula. …