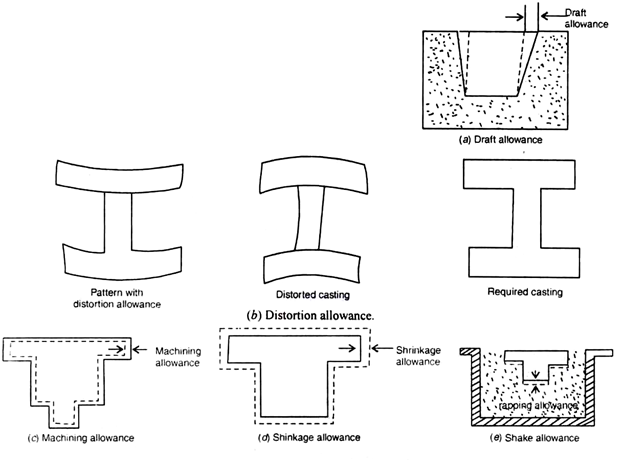

ALL TYPES OF PATTERN ALLOWANCE

(1) SHRINKAGE ALLOWANCE

• The Rate of Construction with temp. is dependent on the material for example constructs to a higher degree compared to aluminium for compensate the solid shrinkage a shrinkage rule must be used in laying out the measurement for the pattern.

• A Shrinkage Rule for cast iron is 1/8 inch longer per foot than a standard rule. If a gear blank of 4 inch in dia was plan to produce out of cast iron,the shrink rule in measuring it 4 inch work actually measure 4-1/2 inch,thus compensating for the shrinkage.

(2) MACHINING OR FINISHING ALLOWANCE

• Provided to compensate for machining on casting.

• Pattern is made Slightly bigger in size.

• Amount of allowance depends upon size and shape of casting, type of material, machining process to be used, degree of accuracy and surface required etc.

• Casting get oxidized in the mould.

• It is the intended to remove surface roughness and other imperfections from the casting.

(3) DRAFT OR TAPER ALLOWANCE

• It is given to all surface perpendicular to parting line.

•Draft Allowance is given so that from the moulding material tightly packed around it with out damaging the mould cavity.

•Provided to facillate easy withdrawal of the pattern.

•Typically it ranges from 1 degree to 3 degree for wooden patterns.

(4) Distortion Allowance

•During Cooling of the mould, stresses developed in the solid metal may induce distortions in the cast.

•This is more evident when the mould is thinner in width as compared to its length.

•This can be eliminated by intially distorting the pattern in the opposite direction

•Sometimes Casting get distored during solidification due to their typical shape.

•Ex:-If the Casting has the form of the letter U.V.T. Or L etc.

•It will tend to contract at the closed end causing the vertical legs for look slightly inclines.

(5) Rapping Allowance

•Before the withdrawal from the sand mould the pattern is rapped around the vertical faces for enlarge the mould cavity slightly which facillate its removal.

•There is no sure way of quantifying this allowance,since it is highly dependent on the foundry personnel practice involved.

•The Magnitude of shake allowance can be reduced by increasing the tapper.

• For Small And Medium Sized Castings, This Allowance can be ignored,but for large sized and precision castings, however Shrinking Allowance is to be considered.