CO2 Sand Reclamation Equipment

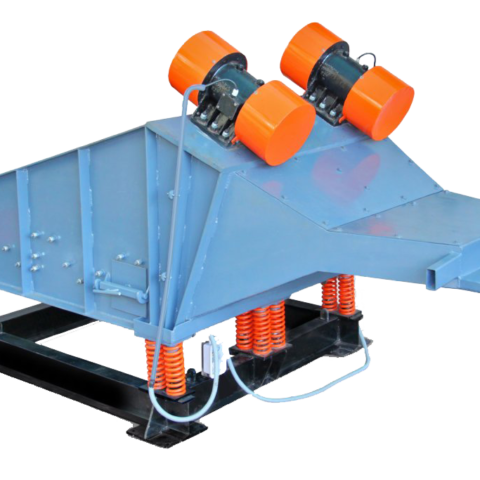

Shake Out machine

BE Shake out machine is simple and robust machine designed for continuous duty to separate castings from sand, sand from flasks and cores from castings. Available in Vibratory and Offset Eccentric shaft.

INLINE KNOCKOUT MACHINE is of free floating twin eccentric shaft design. The main body is supported on a set of coil springs. The rotating eccentric shaft assembly is fitted at the top of the trough. The shaft run on high quality anti friction bearings. The bearings are well protected by housings to eliminate the entry of dust particles, to achieve longer life.

Specification

The Inline Knockout Cum Feeder, Knockout, Vibratory Feeder are available in several sizes, starting from 500 kg to 25,000 kg capacity as standard. Special types also can be designed and supplied to suit customer’s needs.

Features

- Robust Construction.

- Short Cycle time.

- Easy Maintenance.

- Energy Efficient.

- Suitable to remove stubborn sand.

- Designed for continuous operation.

[/gem_list]

Range

- The Inline Knockout Cum Feeder, Knockout are available in several sizes, starting from 500 kg to 25,000 kg capacity as standard.

[/gem_list]

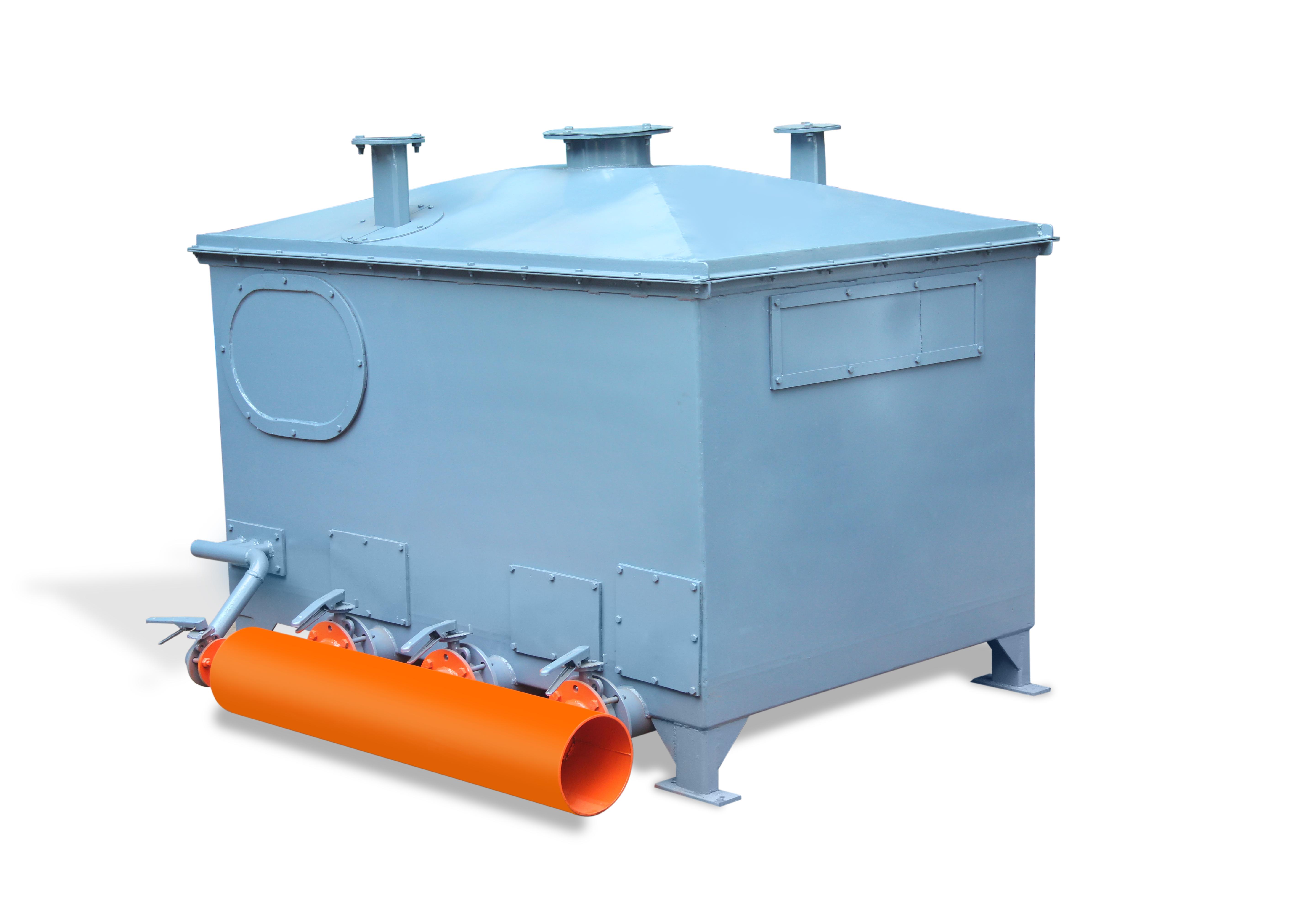

Mechanical Attrition Machine

Features

- Most sturdy design to handle the adverse conditions of Foundry Environment.

- One touch operation.

- Indigenously developed in India.

- Available for CO2 & No-Bake Process.

- Available in customized size & Capacity.

- Low maintenance and Running cost.

- Save environment and production cost by reclaiming the used sand(Baking Sand).

[/gem_list]

No-Bake Sand Reclamation Equipment

Shake Out

BE Shake out machine is simple and robust machine designed for continuous duty to separate castings from sand, sand from flasks and cores from castings. Available in Vibratory and Offset Eccentric shaft.

INLINE KNOCKOUT MACHINE is of free floating twin eccentric shaft design. The main body is supported on a set of coil springs. The rotating eccentric shaft assembly is fitted at the top of the trough. The shaft run on high quality anti friction bearings. The bearings are well protected by housings to eliminate the entry of dust particles, to achieve longer life.

Specification

The Inline Knockout Cum Feeder, Knockout, Vibratory Feeder are available in several sizes, starting from 500 kg to 25,000 kg capacity as standard. Special types also can be designed and supplied to suit customer’s needs.

Features

- Robust Construction.

- Short Cycle time.

- Easy Maintenance.

- Energy Efficient.

- Suitable to remove stubborn sand.

- Designed for continuous operation.

[/gem_list]

Range

- The Inline Knockout Cum Feeder, Knockout are available in several sizes, starting from 500 kg to 25,000 kg capacity as standard.

[/gem_list]

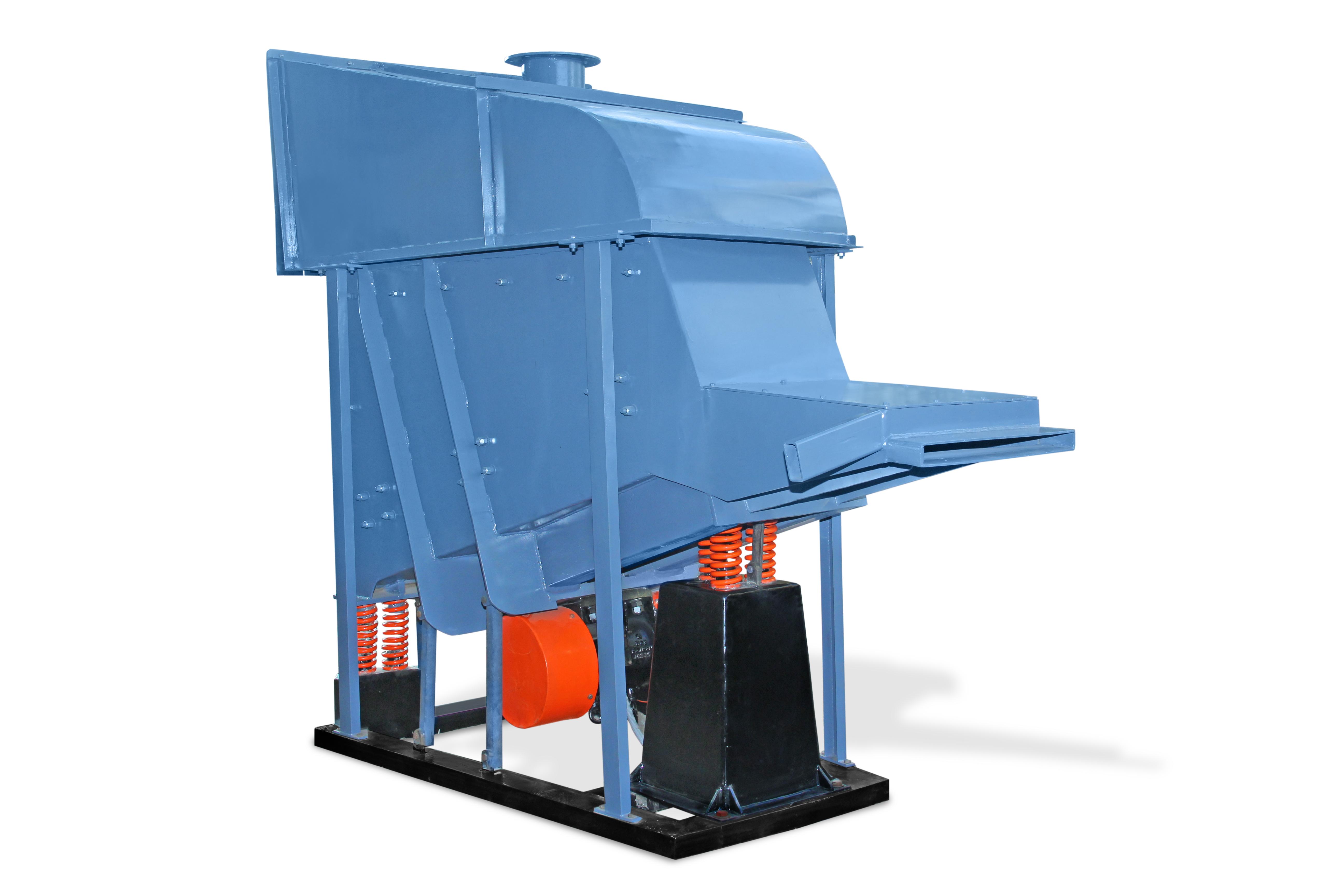

Knock-out with Crusher (Gamma Mill)

The Gamma-Mill Reclamation unit has been designed to break-down, classify, and reclaim chemically bonded sands, using the grain-to- grain attrition principle. The grains of sand subjected to a strong rubbing action, resulting from the vibration of a series of grids and sieves. In this way it’s possible to remove the resin film which covers the grains and therefore to reduce LOI to limited values.

A classifying fluid bed completes the sand treatment removing fines and dust, while a final net sieve withholds any eventual residual impurities. The metallic particle may be easily discharged by means of an opening placed in the back part of the machine.

The gamma mill reclamation group works both as shakeout and Mechanical attrition unit. Ideal not only to reclaim sand mechanically but also to shake out and reclaim it at the same time.

Practically Safety and Economical Feedback

- Sturdy and quality construction.

- Freedom from hammering to clean the casting.

- Helpful in recovering the metal reinforcement rods/ chills/ flow offs usually trapped in sand lumps.

- It consist of a Knockout cum lump reducer.

- Easy Installation.

- Fast return on investment.

- Multiple removable breakdown deck for intensive production and breaking of lumps.

- Perfect Metallic particles separation and simple removal.

[/gem_list]

Sr. No. |

Model No. |

Capacity |

Deck Size (MM) |

Vibrator Motor |

Deck Loading Capacity |

|---|---|---|---|---|---|

| 1 | BE/GM/1 | 1 to 3 TPH | 1500(W) X 1500(L) | 3 HP (2 Nos.) | 2000 Kg. |

| 2 | BE/GM/2 | 1 to 3 TPH | 2000(W) X 2000(L) | 5 HP (2 Nos.) | 4000 Kg. |

| 3 | BE/GM/3 | 3 to 6 TPH | 1500(W) X 1500(L) | 5 HP (2 Nos.) | 3000 Kg. |

| 4 | BE/GM/4 | 3 to 6 TPH | 2000(W) X 2000(L) | 7.5 HP (2 Nos.) | 5000 Kg. |

[/gem_table]

Mechanical Attrition Machine

Features

- Most sturdy design to handle the adverse conditions of Foundry Environment.

- One touch operation.

- Indigenously developed in India.

- Available for CO 2 & No-Bake Process.

- Available in customized size & Capacity.

- Low maintenance and Running cost.

- Save environment and production cost by reclaiming the used sand(Baking Sand).

[/gem_list]

Cooler Classifier

The cooler classifier is put after a mechanical reclamation to de-dust and cool the sand. It is a fluid bed machine, connected with a filtration system, That separates the dust from the sand. In the cooler a double independent circuit of pipes with fresh water circulation it is present inside: the water can be cooled by a cooling tower or Chiller system.

If the customer requires a fixed temperature of the treated sand at the outlet of the cooler, it is possible to connect one pipe circuit with a chiller to satisfy this requirement.

There are different models of cooler classifier with different capacity: from 3 t/h up to 30 t/h.